Select Category

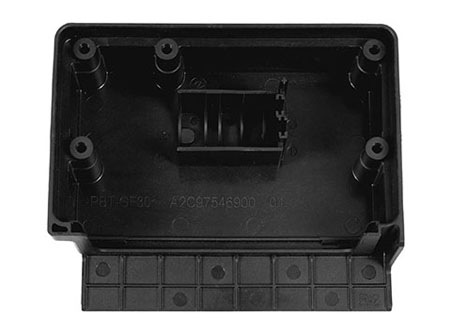

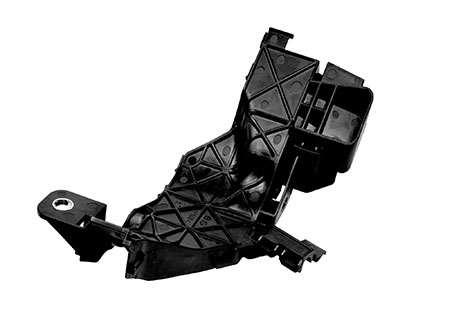

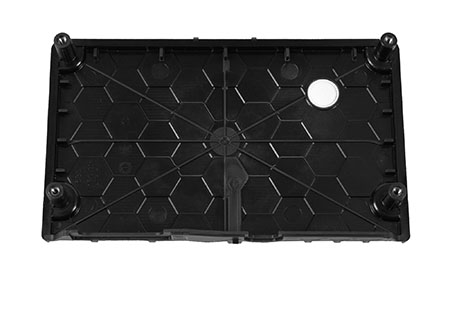

We have in-depth knowledge of the injection moulding process and material properties during processing and use, thus allowing us to provide you with a high-quality end product. With the combined power of cutting-edge machinery,high-end technology and Renata provides best in class quality products to our customers. Our technical molding unit focuses on making parts with the tightest of tolerances.

- We design and manufacture tools to meet our customers strict quality requirements.

- We are equipped with state of the art machines(Fanuc-Engel) with clamping force(30t-300t).

- We have expertise with all engineering plastics and specialty polymers.

- Post-molding activities like Assemblies and testing.

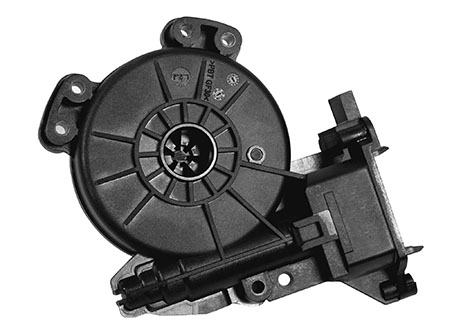

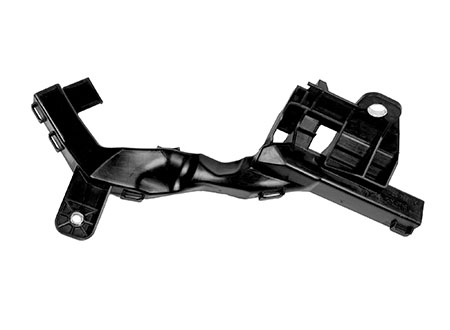

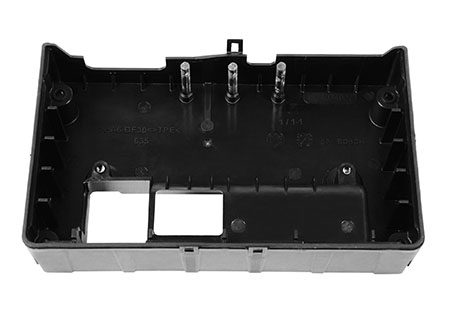

2k or Two Shot molding is one of the most highly sophisticated processes in the plastic industry. We employ highly advanced tool and process engineering to develop the most innovative solutions. 2K injection molding is perfect for combinations of hard and soft plastics and processing two colors in one part.

- We are equipped with state of the art machines(Engel) with clamping force(220t-500t) to ensure precision.

- We design and manufacture tools inhouse to ensure part quality.

- Our engineers are highly experienced with 2k and set parameters to make the best 2K parts possible

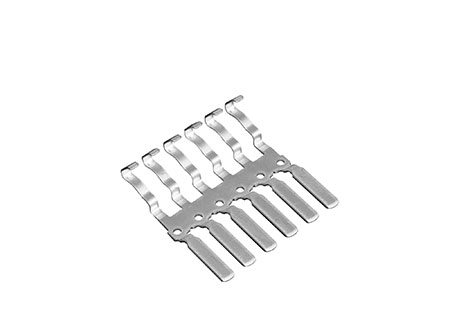

Our stamping department operates Bruderer presses to stamp ferrous and non-ferrous metals at speeds up to 1,500 strokes per minute.Our tools are designed to make quality parts at an economical price for our customers.

- In house press tool-design and manufacturing.

- Range of electronic components, terminals & leadframes, special pins and other parts.

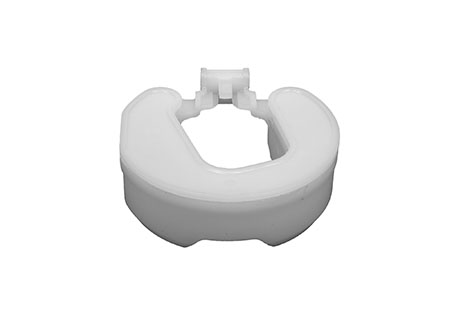

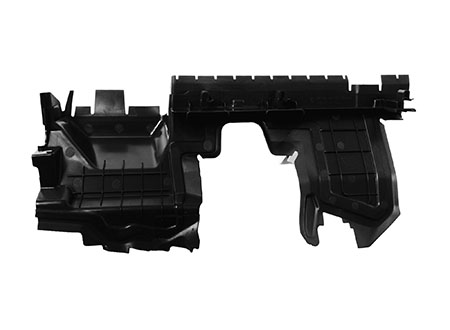

Hybrid moulding or overmolding allows engineers to take advantage of the strength of the composite while enabling complex designs and processing flexibility through injection moulding polymers. We are the single source for everything: Metal inserts are made by our stamping unit and the moulding is done inhouse.Tooling is all inhouse. We also do assemblies,electrical and leakage testing inhouse to to ensure quality of the parts.

- Inhouse design and manufacture of tools.

- Stamping and Insert Moulding.

- Assembly, EOL Testing and automation.

- Both vertical and horizontal machines.

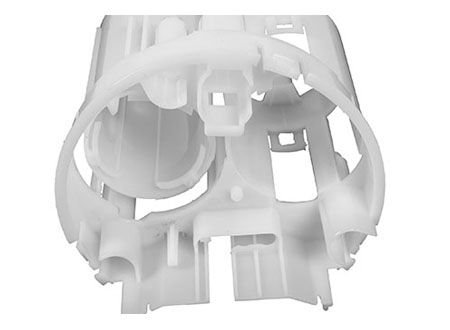

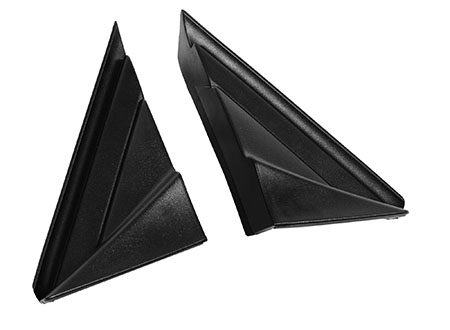

- Inhouse Tool room for captive use.

- State of the art machinery(Makino,Sodick,Charlmilles).

- Tooling team offers design and engineering changes based on customer requirements.

- Multi Component Moulds.

- Metrology, CAD, CAM and flow analysis.